- Certified Company

ISO 9001 : 2015ISO 45001: 2018

- Mail Us

info@technicgroup.hr

MANUFACTURE AND ASSEMBLY OF SWITCH ELEMENTS AND FACBRICATION OF PIPE SYSTEMS

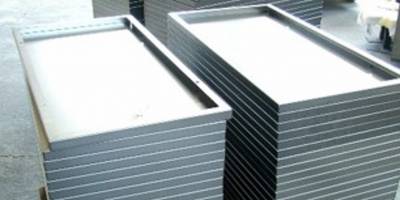

Our production facility serves for assembly of pipe systems, steel constructions, agriculture and marine equipment, as well as for other industries. We provide complete metal works – cutting, bending, manufacturing machine parts, welding, surface lamination and final assembly into finished product.

Fabrication of pipe systems and support

We offer complete production of pipe systems including isometry, assembly planning, pipe processing and documentation. Pipe system assembly is implemented in accordance with the highest quality standards and within agreed deadlines. Our expert team closely monitors all phases of construction.

Cutting

For cutting operations we use lasers with work surface measuring 2500 x 1250 mm and complete computer support and control. One laser cuts blackplates up to 10 mm thick, inox plates up to 4 mm, aluminium plates up to 3 mm. The other laser with power of 2,5 KW cuts blackplates up to 20 mm, inox plates up to 8 mm, aluminium up to 6 mm, which allows for various cutting variations due to many forming options and achieving impeccable precision (0,2 mm), making it the basis for production of different types of casings used in modern electro industry, car industry and other industries. Laser machines are also used for producing complex metal products and semi products. Besides laser and plasma cutting, we also use 3.1meter long hydraulic cutter for cutting common metal sheets up to 8 mm thick and 1200 mm long and up to 6 mm thick and 3100 mm long; inox sheets up to 4 mm thick and 3100 mm long; aluminium sheets up to 8 mm thick and 3100 mm long. Plasma cutting is done by CNC operated standard torch with power of 200A and work surface measuring 3000 ×1500 mm which can cut sheets up to 40 mm thick.

Bending

Cut positions are most commonly processed using cold heading on various segments of sheet by means of straight bending machines, more precisely by one hydraulic press 3 meters long and with the power of 100 tons, and the other one 1,2 m long and with the power of 100 tons. Both machines are CNC operated which guarantees high precision when bending. Their capabilities depend solely on the combinations of the tools they used (matrix and hallmark) and are limited by the maximum power.

Machining

In the part of machining in the workshop there is a possibility of turning on several standard and CNC operated lathe machines, milling, drilling, manual and machine metalwork, which are mainly used in the manufacture of various machine parts, subassemblies and assemblies which are then mounted on the housings or delivered to customers as standalone positions.

Welding

We provide welding of various materials using various procedures TIG, MIG/MAG, REL. We also have welding robot consisting of welding source, robot unit and robot positioner device designed for MIG/MAG welding up to a maximum arc strength of 400 A. The workpiece is placed on the positioner in a repeatable position. By programming the optimal welding parameters, positioning of the workpiece with the positioner and robot unit head movement, welding of the desired position, cross section, continuity, quality and appearance can be obtained.